What Is Tribal Knowledge & Why It’s Critical for Manufacturing

Tribal knowledge is the unwritten, undocumented expertise that lives only in people’s heads. The unofficial adjustments, workarounds, and insights that keep businesses running smoothly but never make it into official procedures. It’s the machinist who knows exactly which sound means the equipment needs attention, the sales engineer who can instantly spot which technical specifications will work for a particular client, or the veteran who understands which supplier relationships require special handling.

In manufacturing environments, this knowledge often centers around equipment quirks and process optimizations. It’s knowing that “Machine #3 runs hot on Mondays after weekend shutdowns, so you need to adjust the temperature settings differently for the first two hours.” It’s recognizing quality issues that don’t show up in standard testing procedures but become obvious to experienced eyes.

The Manufacturing Knowledge Crisis

Based on our experience, this knowledge challenge has reached a critical point. A large number of our highly skilled workforce is retiring now, taking decades of accumulated expertise with them. Manufacturing and industrial sectors face particular vulnerability because so much operational knowledge has traditionally been passed down through apprenticeships and on-the-job experience rather than formal documentation.

The traditional approach to training new employees: lengthy shadowing periods, gradual knowledge transfer, and years-long learning curves, no longer scales with the pace of retirements. A sales engineer might take 18 months to reach full productivity, not because the technical knowledge is impossibly complex, but because so much of the decision-making process relies on pattern recognition and experience that exists nowhere but in senior employees’ minds.

Traditional Documentation Struggles

Most organizations attempt to solve this through traditional documentation—creating standard operating procedures and requiring departing employees to “write everything down.” These approaches often struggle to capture the knowledge that matters most.

The people who possess the most valuable knowledge are typically the busiest and least likely to document it thoroughly. Even when documentation gets created, it quickly becomes static while real processes remain dynamic. The official procedure manual says one thing, but experienced employees have discovered more efficient approaches that never get formally updated.

Static documentation often fails to capture the contextual decision-making that defines expertise. It can tell you what steps to follow, but not how to recognize when those steps need modification or when exceptions apply.

The Dual-Value Knowledge Capture Strategy

If we start capturing tribal knowledge systematically, we don’t have to choose between automation and knowledge retention. We get both benefits from the same effort.

The knowledge we need to retain for people to query and learn from is the same knowledge we need to fuel automations and operations. It’s the same data that serves both purposes.

Think about Bob, your veteran sales engineer. Bob knows everything about your products, your customers, and how to solve complex technical problems. Bob’s always busy, and frankly, Bob’s thinking about retirement in the next few years. We’ve got two problems: we need Bob to be more efficient so he’s not the bottleneck, and we need to capture what Bob knows before he walks out the door.

We don’t have to pick a priority. We can solve both problems with one strategic effort. When we systematically capture Bob’s expertise, we’re helping the business do more in less time and reduce busy-work while retaining that knowledge for the next generation to get up to speed faster.

If Bob’s out in the field, the team can talk to “Bob’s knowledge” and get the answers they need without waiting for Bob to come back. Meanwhile, Bob spends less time doing repetitive work and more time doing what he wants: meeting people in the field, solving compelling problems, and eventually retiring knowing that his insights won’t all be lost when he does.

Where to Start: Follow the Pain Point

Your starting point depends on your most pressing need:

If your priority is seeing immediate ROI (Bob knows it all but he’s always busy): Start with automation that has a clear, measurable return: ideally under 12 months. AI’s moving too fast to push for a 3+ year ROI. Focus on automating repetitive tasks that use Bob’s knowledge, then expand to knowledge retention.

If knowledge access is already a crisis (Bob’s about to retire or he’s completely overwhelmed): Start with data capture and build a conversational interface so people can “talk with Bob’s knowledge” immediately. Once you have the knowledge in the system, you can develop automations on top of it.

Once you start capturing knowledge systematically, both benefits compound over time. The same knowledge base that helps train new engineers also powers the automations that save Bob time.

Real-World Implementation Examples

Here are a couple real-world implementation examples.

Sales Engineering: From 60 Minutes to 20

We’re working with a manufacturing company whose sales engineers create more than half a dozen quotes per day, spending roughly one hour on each proposal. Each sales engineer has developed their own approach to evaluating customer needs, and their own methods for solving and pricing complex customer configurations. New hires shadow experienced engineers for months, gradually absorbing this expertise through observation, many questions and repetition.

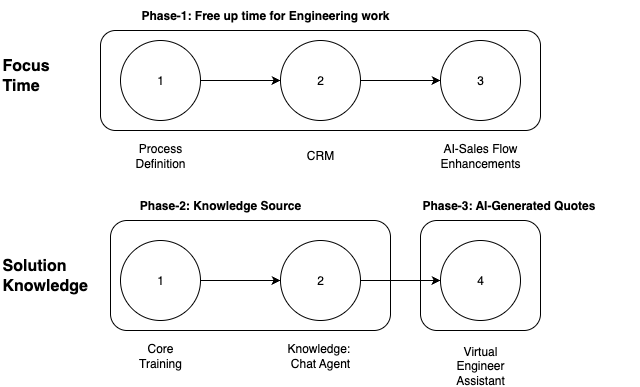

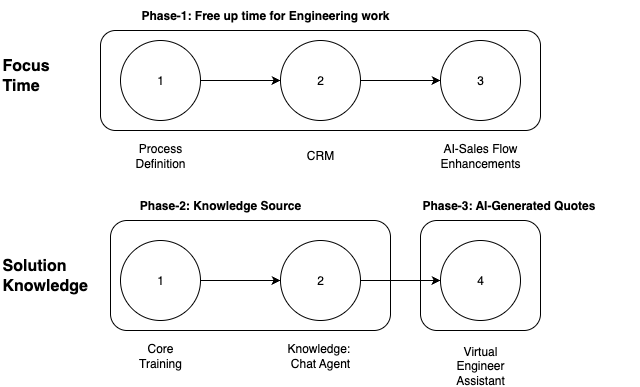

Our knowledge capture implementation follows a two-step process to achieve the 20-minute target:

Step 1: AI-Powered CRM and Sales Process Automation

We’re using AI to automate customer relationship management—automatically emailing and connecting with customers to set up follow-up conversations and chase orders that haven’t closed yet. This handles the relationship management and follow-up workflow that previously consumed significant time.

Step 2: Knowledge Capture for Solution Design

In the subsequent project stage, we’ll be systematically capturing the engineers’ decision-making process through two sub-stages:

Sub-stage 2A: Creating the “Ghost of Engineering Past”

We’re first creating an internal knowledge resource by immortalizing the sales engineer’s expertise so that any new sales engineer can talk to and ask questions of this digital expert. This is particularly critical because the current sales engineers are nearing retirement. Rather than just documenting product specifications, the system captures the reasoning behind specification choices: “For this type of manufacturing environment, with these throughput requirements, under these budget constraints, these three product combinations typically work best.”

Sub-stage 2B: AI-Guided Quote Generation

The final upcoming step is to plug this knowledge system into the quote generation process so that AI can generate preliminary quotes. The expert knowledge acts as a guide to prevent any nonsensical outputs, catching anything totally wrong, and applies their specific solution expertise to ensure accuracy and appropriateness for each customer situation.

This two-step approach achieves the time savings and makes it easier for new engineering staff to assume these roles. New sales engineers can access decades of accumulated expertise through intelligent systems that understand both technical requirements and customer relationships, augmenting their judgment with institutional knowledge that would otherwise take years to develop.

Product & Solution Knowledge: The “Unit B-428” Challenge

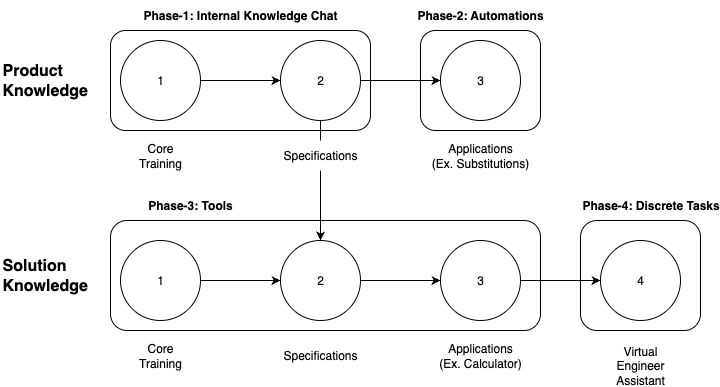

We’re working on a second implementation that addresses complex product and solution expertise in B2B manufacturing support. The challenge: “Unit B-428 works as interim replacement for C-29, but only under specific conditions related to operating temperature and integration with existing systems.”

This knowledge exists primarily in the minds of experienced solution experts who’ve spent years learning which products work in which situations, which combinations create problems, and which workarounds solve specific customer challenges. When customers call with equipment failures, the response quality depends entirely on which expert happens to take the call.

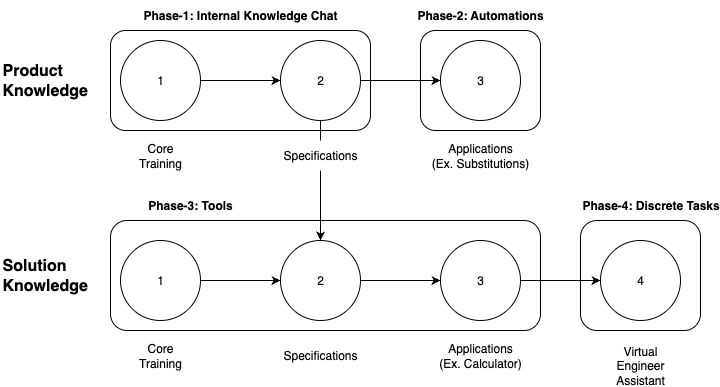

Our knowledge capture approach requires dual tracking: product knowledge (understanding what each unit can do under various conditions) and solution knowledge (knowing how to approach different types of manufacturing problems). This means systematically documenting not just product specifications, but the reasoning process experienced engineers use to diagnose problems and recommend solutions.

The business impact extends beyond faster problem resolution. Consistent recommendations across the organization, reduced dependency on individual experts, and the ability to leverage institutional knowledge are transforming how the company approaches customer relationships. Junior engineers can access the collective wisdom of senior experts, while experienced engineers focus on complex edge cases rather than routine problem-solving.

Both implementations show that successful knowledge capture requires understanding not just what experts know, but how they think through complex problems and make decisions under uncertainty.

Taking Action on Tribal Knowledge

Ready to start your own dual-value knowledge capture? Start with these three steps:

Step 1: Map Your Risks and Opportunities

Ask yourself these questions:

- Which knowledge exists only in people’s heads that’s most critical to operations?

- Do I have immediate problems I need to address through automation?

- Are there things I wanted to automate before but couldn’t because they required personal knowledge and experience?

- Do I have anyone at risk of retiring in the next 2-3 years?

- Am I stuck with hiring issues where we can’t afford to take someone out of their role to train, but we need more staff to perform certain functions?

Step 2: Talk to Your People

Gather feedback from your team around areas where they’re feeling pain, problems, and wishes. Often the best automation opportunities come from people saying “I wish we could…” or “It’s frustrating that I always have to…”

Step 3: Find Your Bottlenecks

Look at your processes and figure out where operations get stuck because of people, process, or system bottlenecks. AI makes new things possible, but the fundamentals are the same: people, process, and bottom-line optimization.

Your Minimum Viable Start

The minimum approach is a single quantifiable automation that has an ROI between 6-24 months, ideally under 12 months. It should be an automation that relates to the role you want to capture knowledge from and should either augment their work (an AI interface they use) or reduce their workload (doing repetitive work using their knowledge).

Anything you build needs enough initial good data to be useful, and then it has to be nurtured and improved over time. You can’t build it once and expect it to be done, it’s a commitment. Focusing on ROI makes that commitment practical and tied to real outcomes.

The specific methods for capturing tribal knowledge, from interview techniques to data extraction approaches, will be covered in a future article. For now, start with mapping your biggest knowledge risks and automation opportunities.